Energy Efficient Units

Treforest Glass offer a range of glass types, coatings, spacers and gases in order to manufacture energy efficient units that comply with current building regulations, as well as units that achieve beyond current regulations.

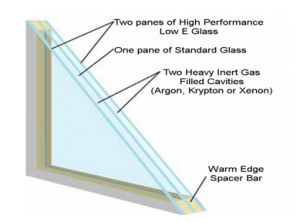

The makeup of a sealed unit has a part to play in the overall energy efficiency of a building. Firstly, there is direct heat loss, normally measured in u-values, which is the loss of heat over a particular area, measured in time. The slower the heat escapes, the better. In recent years, glass manufactures have achieved better results with Low-E (low emissivity) glass such as Pilkington’s KS or KS 1, Saint Gobain’s Planitherm Total + or Guardian’s Planitherm One II, which are all soft coated glass to prevent energy escaping.

In addition to soft coated glass, we use warm-edge spacer bar which acts as a thermal break inside the unit. This helps preventing the transfer of cold air into the room, and warm air out of the room, thus reducing the risk of condensation. Most of the heat loss from a window travels through the edge of the glass. The warm-edge spacer helps, as its name suggests, keep the edge of the unit warmer.

We also fill the cavities of our units with inert gases, such as Krypton or Argon, which helps create insulating pockets, thus improving levels of insulation.

Benefits Of Energy Efficient Units:

- Ensuring homes are warmer in winter and cooler in summer.

- Making savings on energy bills.

- Reducing carbon emissions.

- Reducing condensation.

- Complying with building regulations.

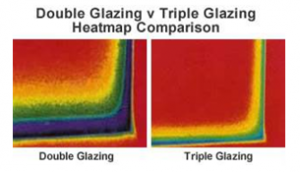

Triple & Quadruple Sealed Units

The benefits of energy efficient glass, spacers and gases can equally be applied to triple and quadruple glazing to achieve even better performing units.

Building Regulations

Part L – Conservation of energy fuel and power

Windows need to provide minimal heat loss ensuring lower energy use thereby reducing CO2 emissions. A u-value is a measurement of heat loss and it is this, along with the way windows are fitted, that will ensure compliance. Alternatively, windows are now also given energy ratings from A-G in a similar way to your fridge or freezer, where A rated products give better thermal performance than those rated G. Building Regulations now require replacement windows to be C or better.

U-Values and WER's

U-values are the standard unit of measurement used in Building Control legislation to specify the thermal insulation requirements of various elements in a building. They indicate the rate of heat loss from inside to outside.

Current building control legislation for windows requires a u-value of 1.4 W/m2K for new build residential properties and 1.6 W/m2K for replacement windows in existing properties. To avoid confusion, these figures relate to the overall system Window Frame and Glass.

As a Rule of thumb a sealed unit which provides a 1.2W/m2K centre pane u-value with the benefit of Low Iron on the external pane (for thermal gain), a Warmedge spacer (to act as a thermal break) and argon gas will generally achieve a 1.4W/m2k as an overall system figure when using a Timber Window with a 70mm Frame. This is in accordance with the Thermal Rating Register. Most joineries these days has access to a Timber calculator which will take into account the frame and glass.

To find out what you require in UPVC or Aluminium frames you need to check with your ‘system’ company who will check on their calculator which will tell you what to use to conform to Building Regulations or to achieve a particular Window Energy Rating, or for particular projects which require higher performance windows and glass to conform to the overall Building Performance.

Get in Touch

Treforest Glass offer many specifications that can improve energy efficiency performance in a wide variety of situations, whether residential or commercial. Please CONTACT US to discuss your requirements.